Manufacturing IoT

Dashboard Redesign

Transforming a cluttered industrial monitoring system into an intuitive, dark-mode experience for global manufacturing operations.

Global OEE

87.3%

Plants

247

The Existing System

A cluttered, difficult-to-navigate interface that left users struggling to connect high-level data with machine-specific details

Low Visibility

Light mode made status colors (Red/Green) hard to read on bright factory floors.

Navigation Trap

Users couldn't easily move back up the hierarchy, getting lost in nested views.

Disconnected Data

3D visualizations had no clear connection to performance metrics and charts.

Redesigning for Global Scale

The client had a manufacturing monitoring system that captured global data, but the interface was cluttered and difficult to navigate. Users struggled to move between high-level maps and specific machine details without getting lost.

Role

Lead UX Designer

Tools & Methods

Heuristic Evaluation, Persona Development, Information Architecture, Figma, FigJam

Deliverables

UI Audit, Information Architecture, High-Fidelity Prototypes

My Goal

Redesign the experience to improve visibility, navigation, and readability for factory operators and executives.

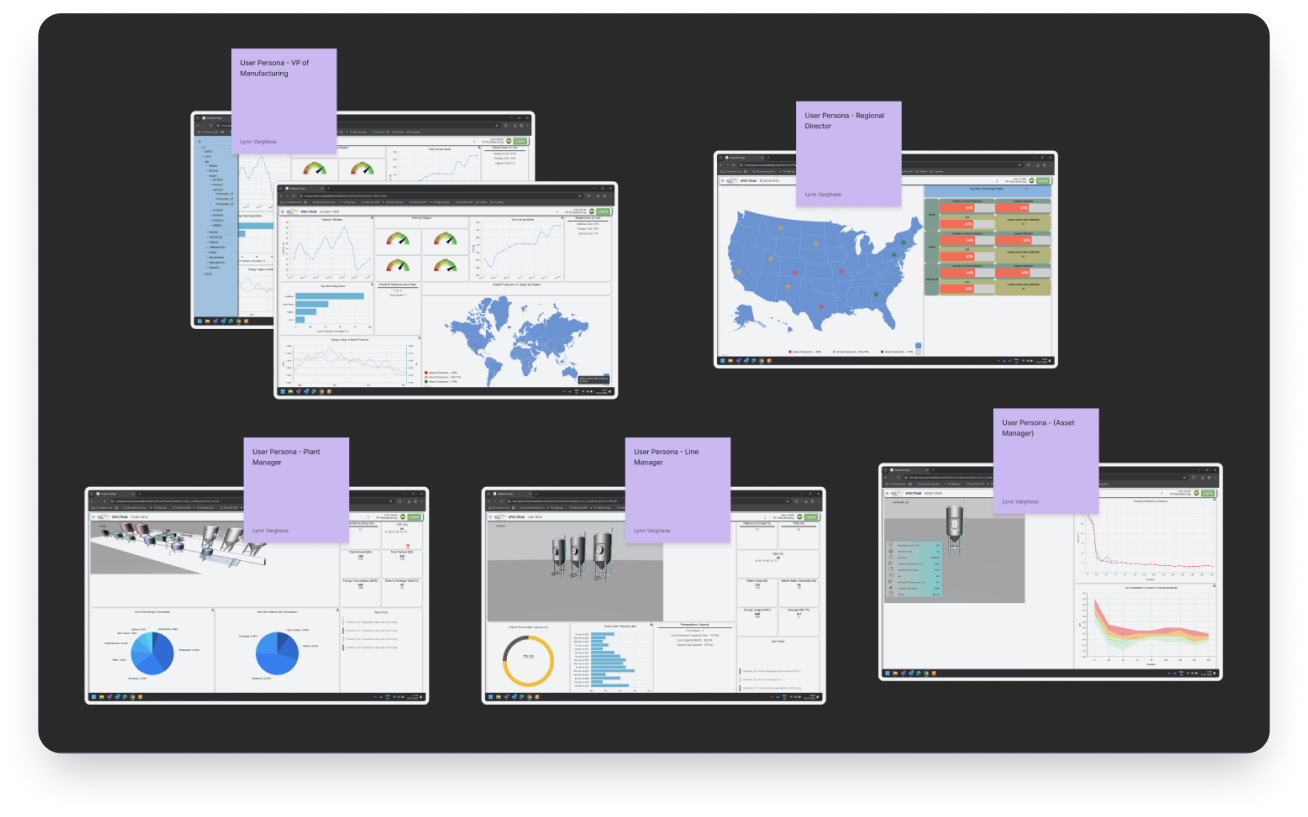

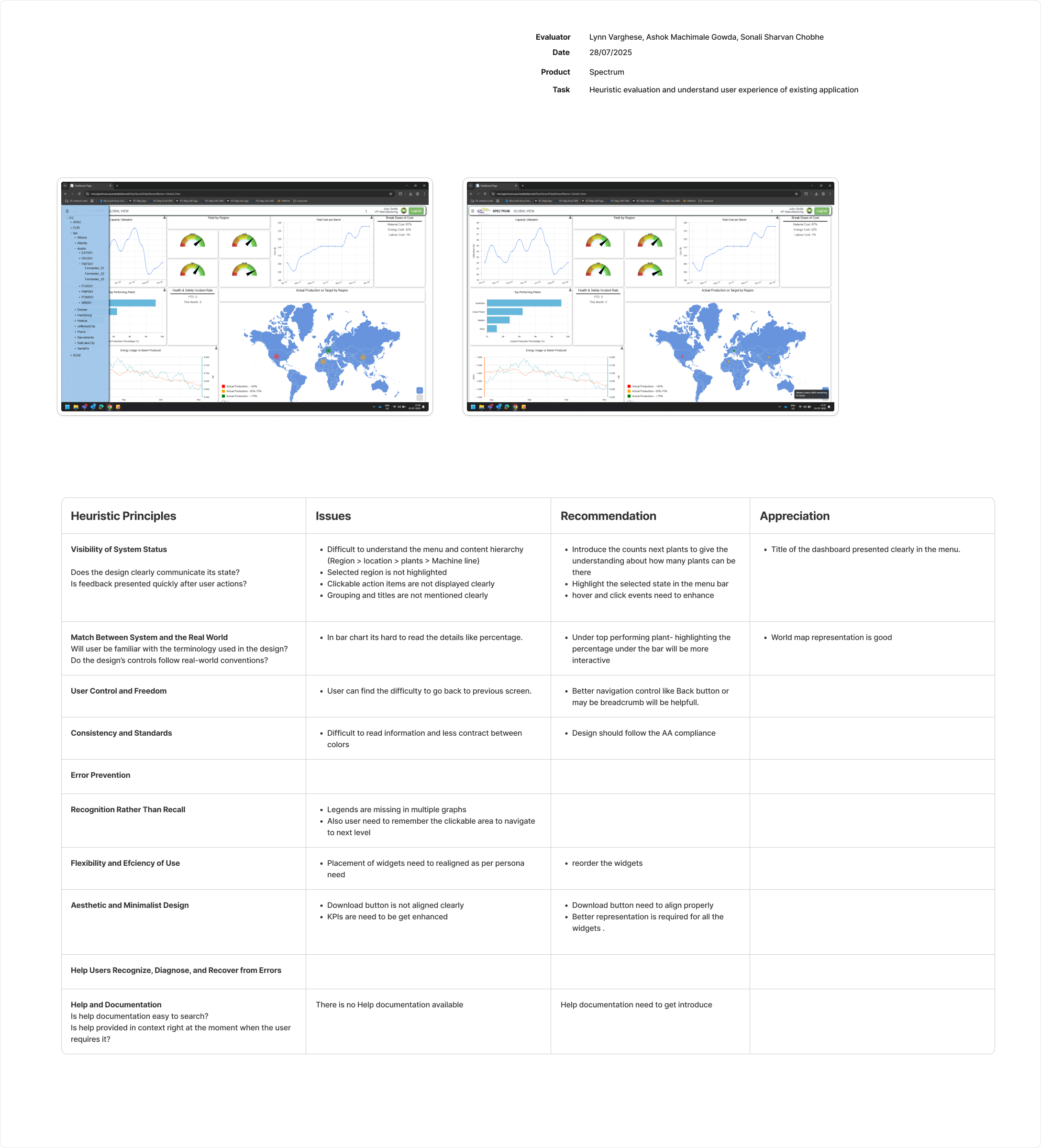

Heuristic Evaluation

Rigorous analysis using Nielsen's 10 Principles across multiple user personas

VP of Manufacturing

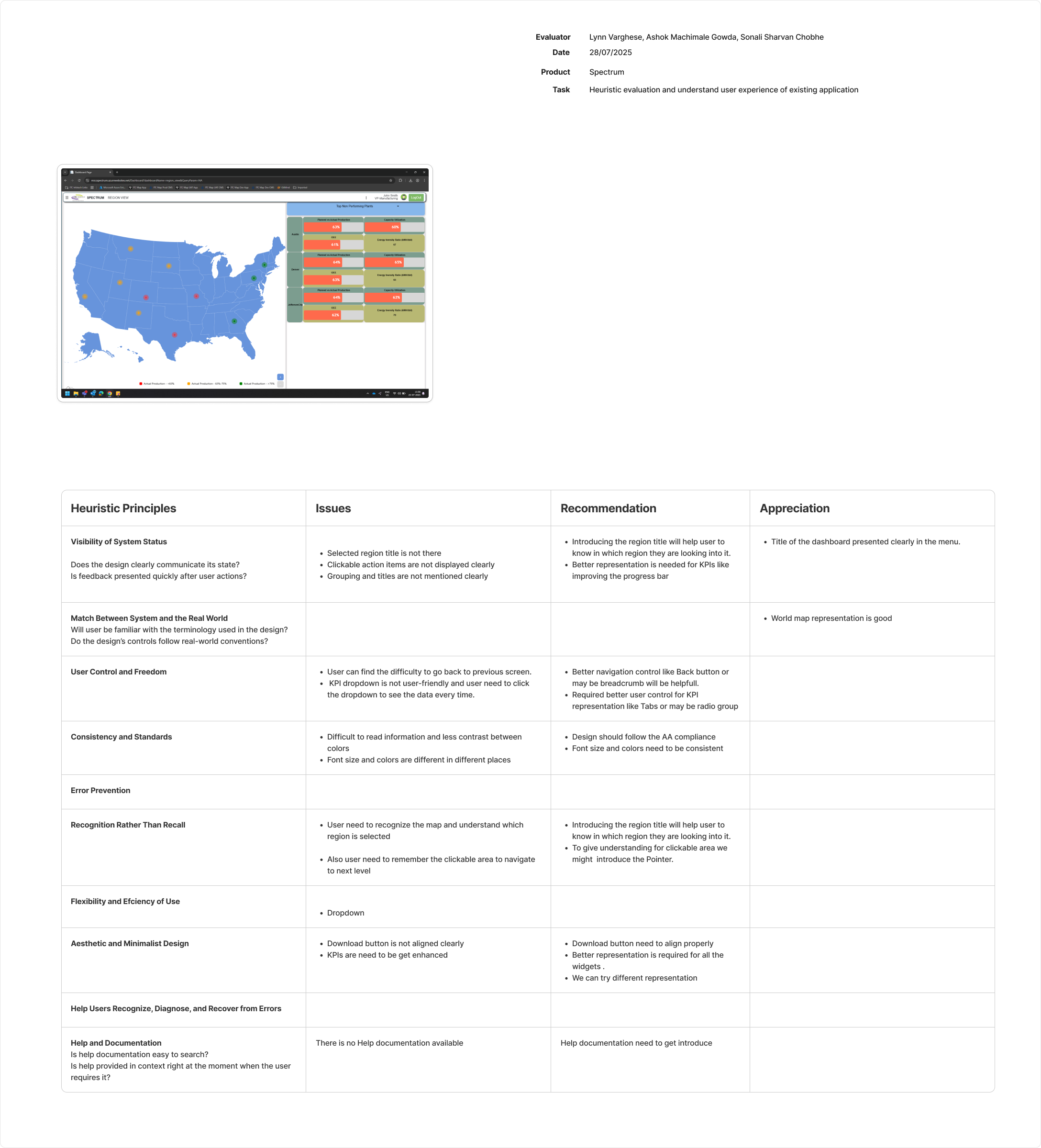

Regional Director

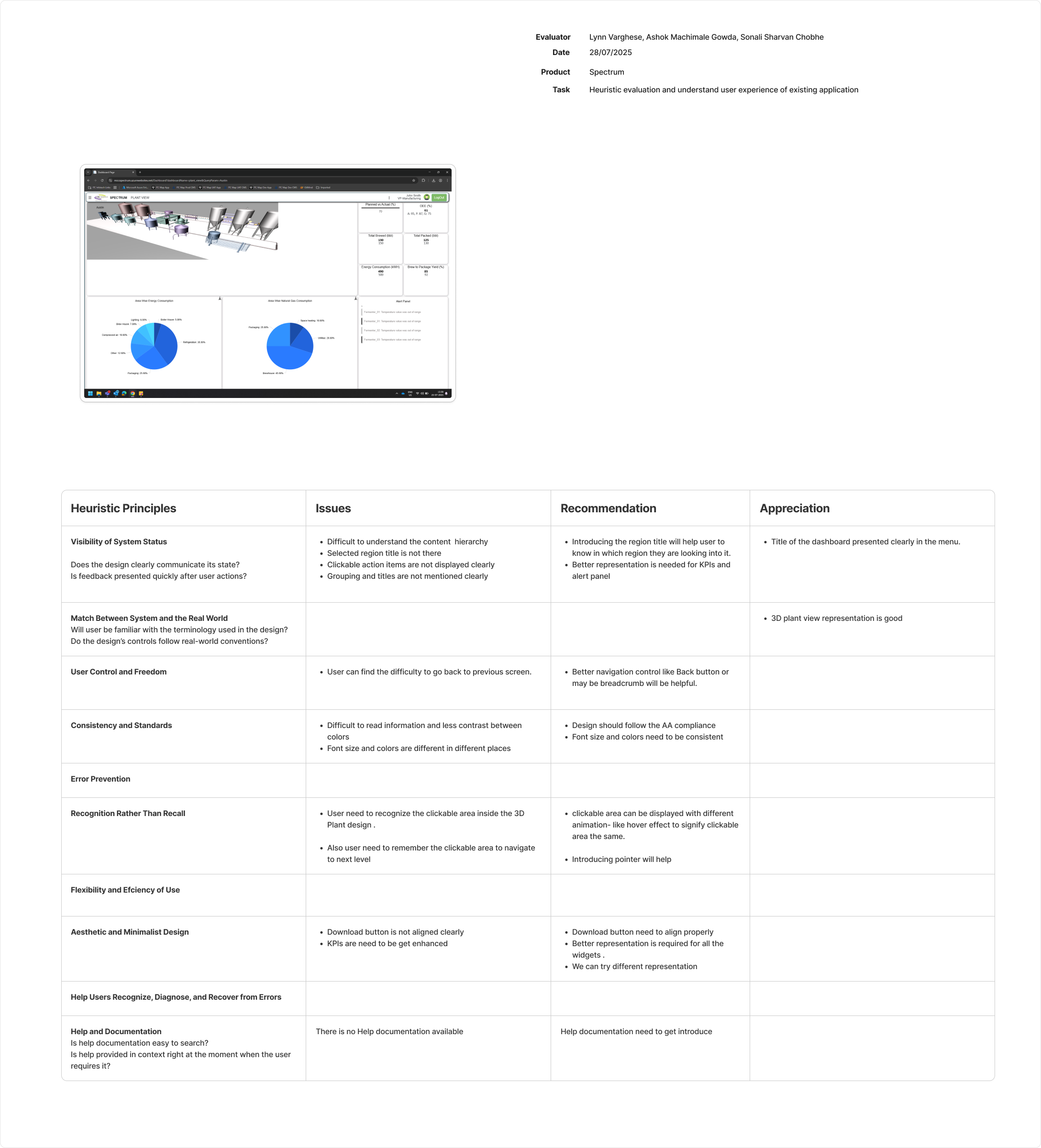

Plant Manager

Line Manager

Quality Manager

Key Findings

Navigation Trap

Users couldn't go "back" up the hierarchy easily, getting lost in nested views

Low Visibility

Light mode made it hard to read status colors (Red/Green) on factory floors

Mystery Meat Nav

Clickable areas in the 3D view weren't obvious, causing confusion

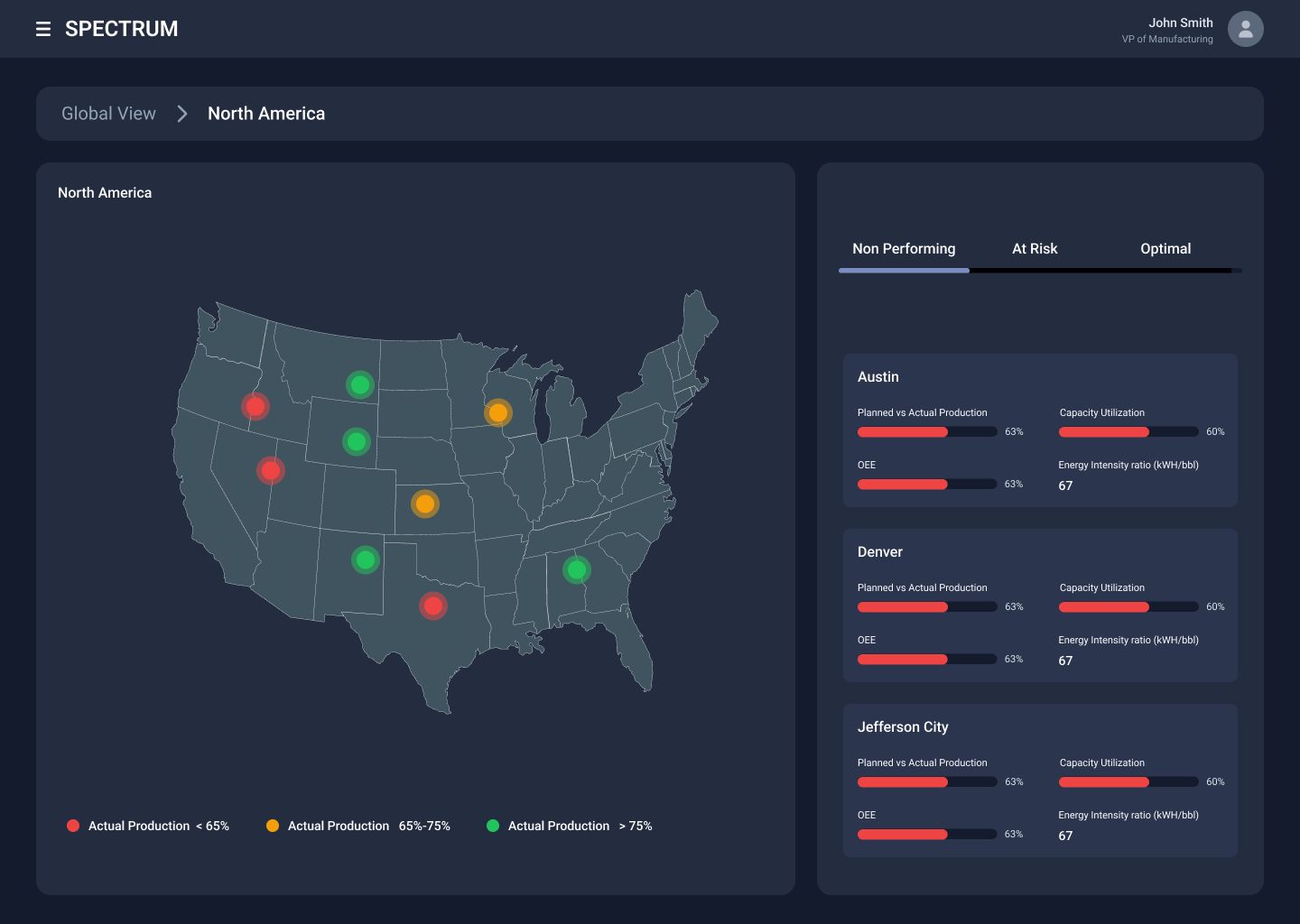

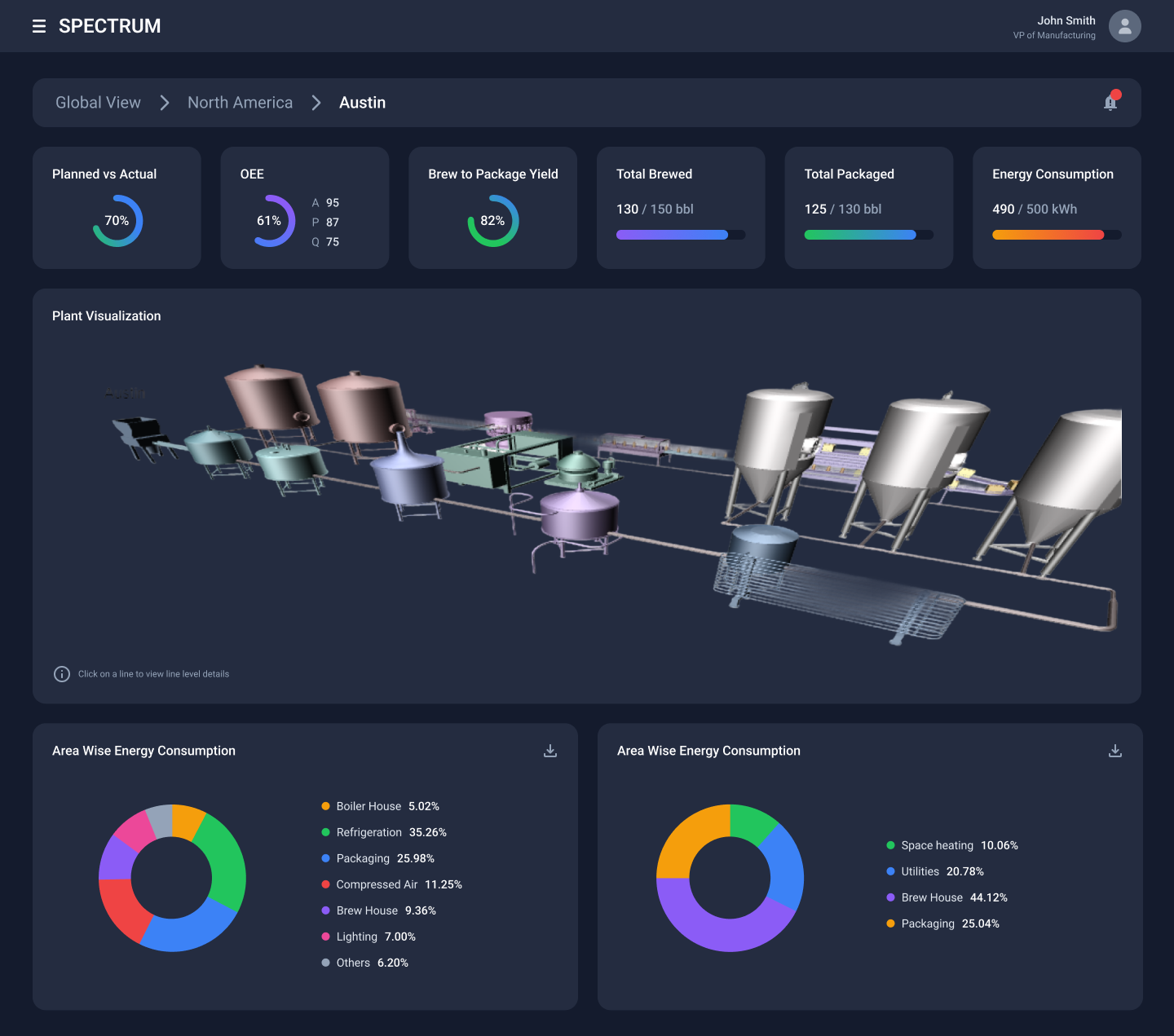

The Redesigned Experience

A scalable, intuitive dashboard with dark mode, integrated visualizations, and seamless navigation

VP of Manufacturing

Global overview dashboard with high-contrast dark mode, organized card layouts showing KPIs, regional breakdowns, and plant performance at a glance.

Regional Director

Interactive US map with color-coded plant status (red/yellow/green), tabbed performance filters, and detailed metrics for Austin, Denver, and Jefferson City plants.

Plant Manager

Austin plant with isometric 3D facility layout, integrated KPIs showing OEE and production metrics, plus area-wise energy consumption bar charts.

Line Manager

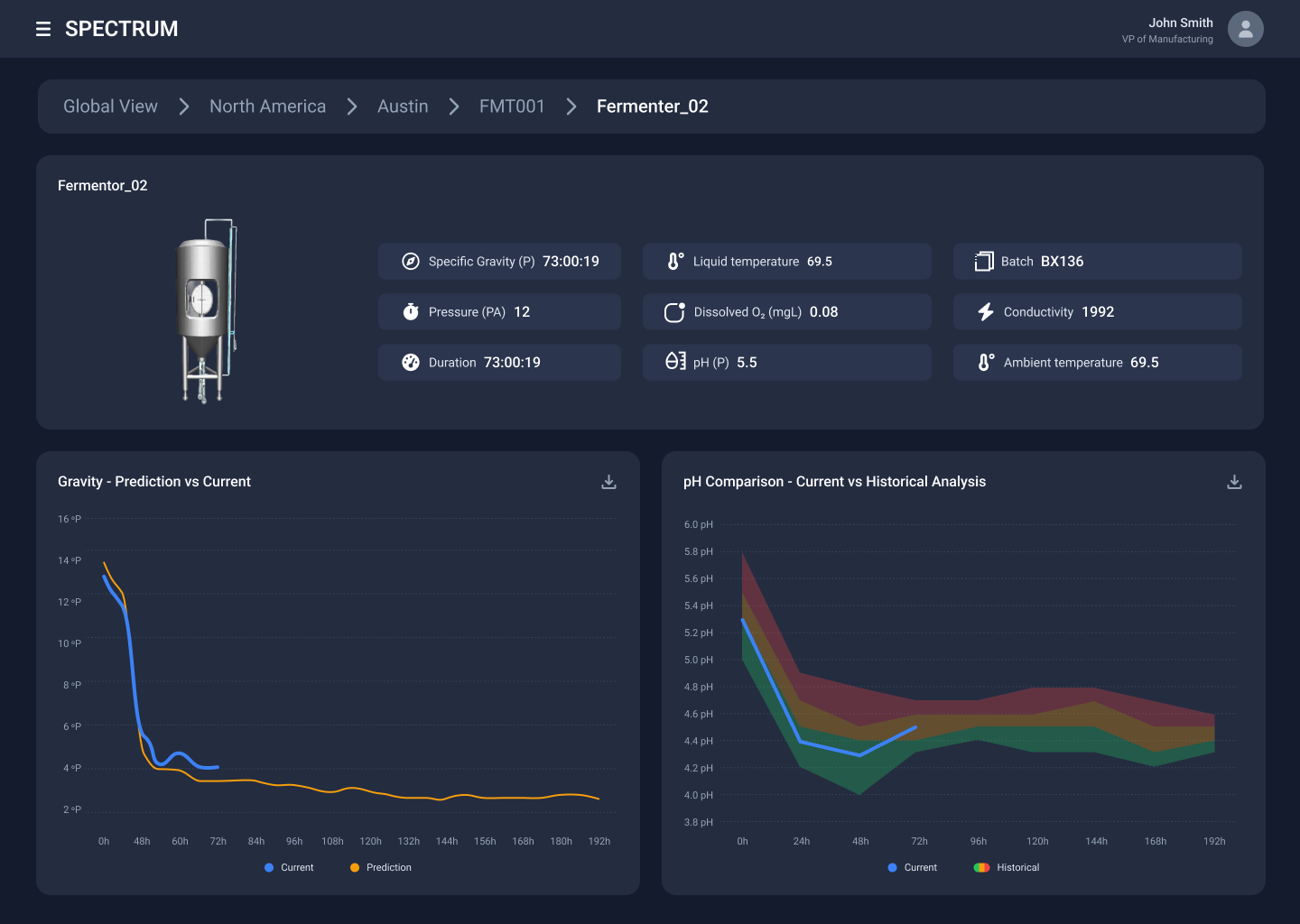

Fermentation line (FMT001) displaying multiple 3D tank assets with individual status indicators, current batch information, and consolidated performance data.

Asset Manager

Individual fermenter (Fermenter_02) with detailed 3D digital twin, real-time temperature and pressure parameters, and historical trend comparison charts.

Impact & Conclusion

By grounding the redesigned MVP into a scalable, intuitive tool

Clear Navigation

Breadcrumb system eliminated user confusion

High Visibility

Dark mode improved readability

Faster Decisions

Reduced diagnostic time

Scalable System

Supports global expansion

The new design significantly reduced the cognitive load for operators managing complex industrial assets across a global manufacturing network.